What are the common raw materials of packaging gift boxes?

The materials of gift boxes commonly used in life are mainly paper packaging boxes, wooden packaging boxes, leather packaging boxes, plastic packaging boxes and metal packaging boxes. They are all suitable for the use of business gift boxes and personal gift boxes. The paper gift box materials can be divided into the following types: white cardboard, gold and silver cardboard, coated paper, white paper, fancy paper, double adhesive paper, etc.

1. Gift wine box reference gift box category:

(Single Coated Art Paper ), or white paper with gray background. Larger boxes can be mounted by250 GSM + 250 GS, as well as gold and silver cardboard. Different materials should be selected according to actual needs and product grades.

Printing: Mostly print with 4C + 0C or 4C + 1C, you can print spot colors, gold or silver.

Back-end process: there are gloss glue, matte glue, local UV, matte, hot platinum (metal texture film with gold, silver, gem blue and other colors to choose from) or anti-counterfeit film (so that others cannot imitate), Hit bump, beer, sticky and other processes.

2. Moon cake gift box:

Mostly use 157g coated paper to mount double gray boards or white boards, but also use cloth pattern paper or other special craft paper.

Printing: Mostly printed in 4C + 0C, can print spot colors (special gold or special silver).

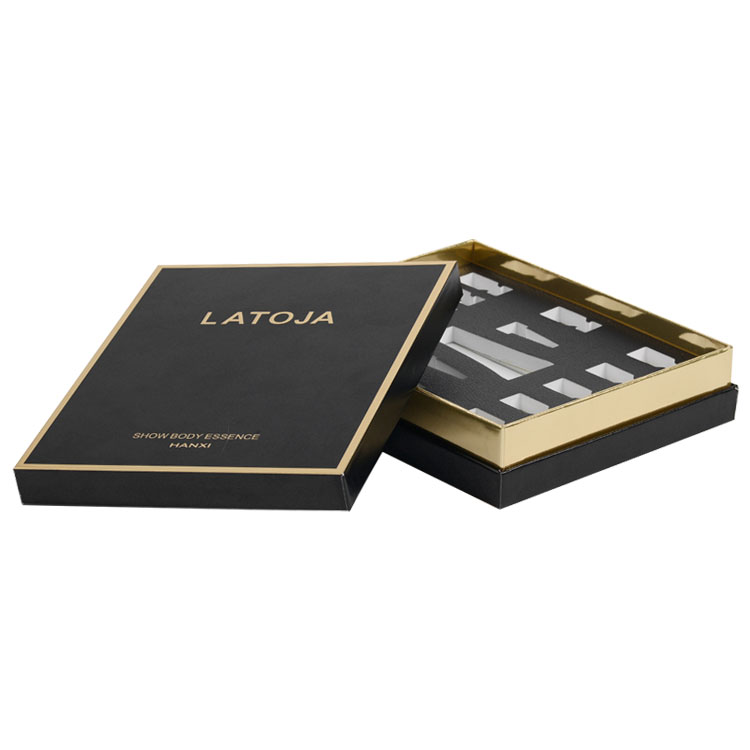

Back-end process: There are over-gloss glue, matte glue, local UV, matte, embossing, hot platinum (metallic film with gold, silver, jewel blue and other colors to choose from) or anti-counterfeiting film (Imitation), the inner box is commonly used styrofoam mounted silk velvet, sponge or flocking plastic. Later craftsmanship is mostly made by hand. The selection of materials should be based on product needs and grades. It has a beautiful and elegant artwork.

3. Health-care gift box:

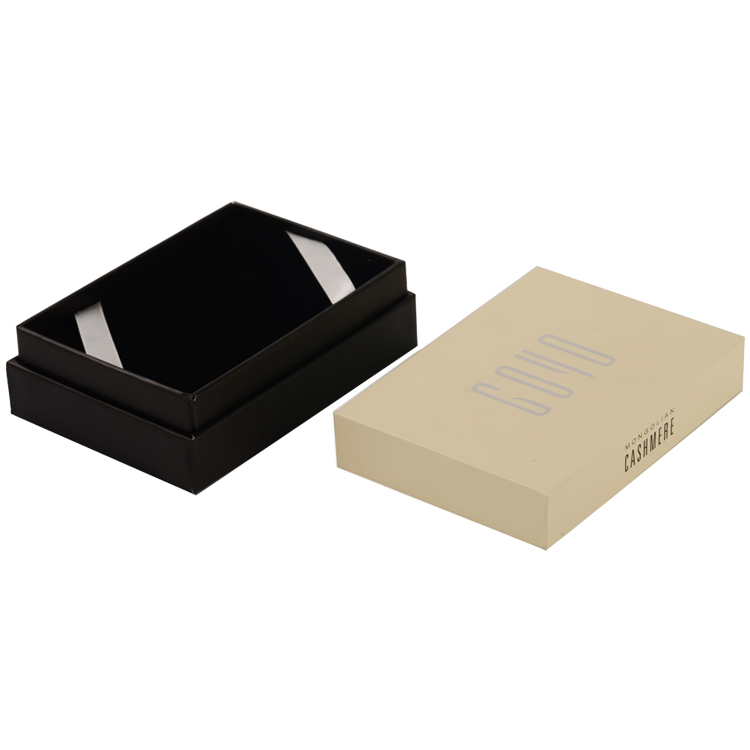

Mostly use 157g coated paper to mount double gray boards or white boards, but also use cloth pattern paper or other special craft paper.

Printing: Mostly printed at 4 + 0C, you can print spot colors, gold or silver.

Back-end process: There are over-gloss glue, matte glue, local UV, matte, embossing, hot platinum (metallic film with gold, silver, jewel blue and other colors to choose from) or anti-counterfeiting film (Imitation), the inner box (inner card) has a model type and a partition type, and the model type is usually foamed plastic mounted silk velvet cloth, sponge or flocking plastic. Later craftsmanship is mostly made by hand. The selection of materials is based on the needs and grades of the products to ensure beauty and economy.

4. Electronic gift boxes:

Such as MP3, U disk or mobile phone box. The materials are mostly 157 ~ 210g coated paper or matte paper, and 800 ~ 1200g double gray boards are mounted. It can also be cloth-textured paper or other colored special craft paper.

Printing: Mostly printed in 4C + 0, can print spot colors (special gold or special silver).

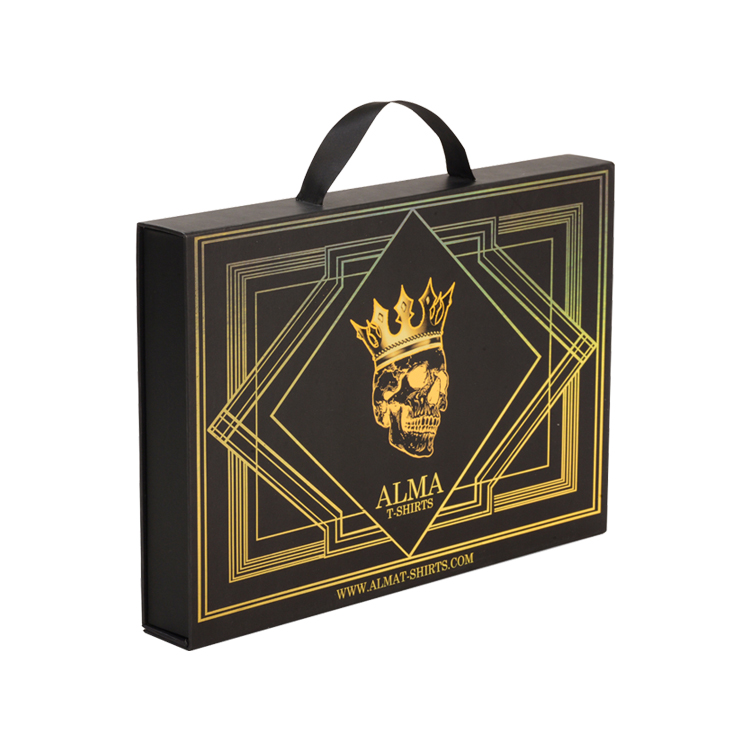

Back-end process: there are gloss glue, matte glue, partial UV, embossing, hot platinum (metallic film with various colors such as gold, silver, gem blue, etc.) or anti-counterfeiting film (making it difficult for others to imitate) The inner mounting paper is 157g coated paper, which is not printed.

Inner box (inner card): commonly used styrofoam lined with silk velvet, sponge or flocking plastic. Two magnets are embedded in the opening of the box, and the subsequent processes are mostly made by hand. This shape is a book box type, and the materials are selected according to the actual product needs and grades to ensure vibration resistance, beauty, economy and fashion.

5. Ordinary mobile phone packing box:

Mostly use 250 ~ 350g white or gray cardboard, 4C + 0 printing, and mount W9 (white), B9 or C9 pit (yellow).

Printing: It is usually printed at 4 + 0C, and spot colors can also be printed.

Back-end process: there are over-gloss glue, matte glue, partial UV, hot platinum (metal texture films with gold, silver, sapphire blue and other colors to choose from) or anti-counterfeiting film (difficult to copy), inner box Card) can be made of styrofoam, paper tray, sponge or flocking blister. Materials such as paper or plastic should be selected according to the actual needs of the product to ensure stability, beauty, economy and practicality.

6. IT electronic products:

There are many such varieties, such as motherboards and graphics cards. Mostly use 250 ~ 300g white card or gray card paper, four color printing, and mount W9 (white) or B9 (yellow) pits.

Printing: Mostly printed in 4C + 0, can print spot colors.

Back-end process: There are over-gloss glue, matte glue, partial UV, hot platinum (metal texture film with gold, silver, sapphire blue and other colors to choose from) or anti-counterfeiting film (difficult to copy) ) Often use pit paper or cardboard as the material, and reasonable design according to the structure of the content. It can also be made of styrofoam, paper tray, sponge or flocking blister. The selection of materials should be in accordance with the actual needs of the product to ensure beautiful, stable, and economical.

7. General electronic product packaging box:

Mostly use 250 ~ 300g white card or gray card paper, four color printing, and frame W9 (white), B9 or C9 (yellow) pits.

Printing: Mostly printed in 4C + 0, can print spot colors.

Back-end process: there are over-gloss glue, matte glue, partial UV, hot platinum (metal texture films with gold, silver, sapphire blue and other colors to choose from) or anti-counterfeiting film (difficult to copy), inner box Cards) often use pit paper as a material and are reasonably designed according to the structure of the contents. It can also be made of foam, paper tray, sponge or flocking blister. The selection of materials should be in accordance with the actual needs of the product, to ensure the product's bearing capacity, stable vibration resistance, beautiful and economical.